About the Shaving Horse

The shaving horse is a simple foot-operated vice that allows you to hold a piece while having both hands free to work. A shaving horse is relatively easy to build and extremely useful to anyone who uses hand tools to shape spindles for turning, chair legs, barrel staves, shingles, and the like. It is traditionally used with a drawknife or spokeshave, but can be adapted for use with other tools. For example, by holding a rabbet plane in the dumbhead, you can shape thin stock by drawing it against the iron.

In Das Hausbuch der Mendelschen Zwölfbrüderstiftung in Nürnberg, there are a couple of depictions of what may be shaving horses (such as this link) as used by coopers, pushing the date back to 1485, though these may be another form of holding device. The precise origins of this tool may never be known, but by the 17th century, shaving horses are clearly used in chairmaking, turning, coopering, and many other trades.

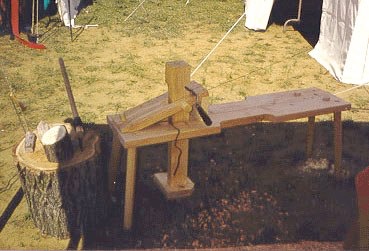

The traditional European form for a shaving horse (called the "Continental" style or "Dumbhead" style) has a post that pivots through the center of the bench and ends in the dumbhead (the head of the vice, with an "L" or "T" shape). It's easy to construct and has very few parts.

The shaving horse is traditionally a shop-built (or home-built) tool, so there are countless variations on its design. If you are interested in building one, I would suggest beginning by examining as many examples as you can and choosing one that matches the way you work and your woodworking skills. My example below requires very few tools or joinery skills, but you may prefer something fancier or more versatile. Likewise, you will want to experiment a bit as you assemble it to find the size and proportions that are comfortable for you.

Most of what we know about shaving horses (or at least what is published in English) is based on those used in England and America in the 19th and early 20th centuries, mostly in rural areas. Whether or not this is any different than what a 16th century urban tradesman might use, we do not know. Like most shop-made tools, I doubt there was enough standardization that we will ever really know, so I would go with what appeals to you.

Most shaving horses are built on the same basic platform, a stake-leg bench (usually with four legs, but occasionally with three). Really fancy ones may include a pivot at one end so that it is stable on uneven ground. As a starter, a simple four-legger does nicely.

The bench should be at least long enough that you can sit and reach the work comfortably. Some benches are longer, and double as work benches for sawing, boring, etc. Mine is 4 feet by 11 inches by 1-3/4 inches, with cutouts for my knees at about the midpoint. The height is also a matter of preference, mine is 17-1/2 inches high, which works adequately but might stand to be a bit higher (I have long legs).

The bench itself is very easy. Measure and cut the board to length and width. In each corner, bore a hole for a leg. The holes should be angled so that the legs will splay out in both the width and length of the bench. Try this first with some scrap wood to get your technique down. The angles of the holes do not need to match exactly, but the closer they are the better. The tenon at the top of each leg will fit into these holes, so choose a bit size that is large enough to be strong (no smaller than 1 inch) but not larger than the size of the stock you plan to make the legs from. If you make your legs from 2-by stock, a 1-1/4 inch bit works fine.

The dumbhead is cut from a single piece of 4 by 4 stock, and is about 26-1/4 inches in length.

Originally I used a square "tread" on the end,

but recently I replaced it with a keyed dowel,

which is a bit easier to remove and replace.

The bridge is made from an upright about 4-2/4 inches high, and a plank about 17 inches long. The mortise for the dumbhead runs from about 8-1/2 inches to 14-3/4 inches from the lower end of the bridge. The pivot for the dumbhead is 8-1/2 inches long and 3/4-inch in diameter.

Other sources on shaving horse construction include:

Landis, Scott. The Workbench Book. Taunton Press, Newtown, CN, 1987.

Underhill, Roy. The Woodwright's Shop. University of North Carolina Press, Chapel Hill, NC, 1981.

Copyright 2009, Thomas Rettie.