Lathes Part 4:

Building a Portable Spring Pole

Lathes Part 4:

Building a Portable Spring Pole

In theory, a springpole is quite simple: all you need is something springy overhead, such as a tree branch. If a tree isn't conveniently located, you can approximate one by standing the branch up on a tripod of sticks. If you work indoors, you just attach said branch to the rafters of your shop and have at it.

Unfortunately, reality is not always as simple as theory.

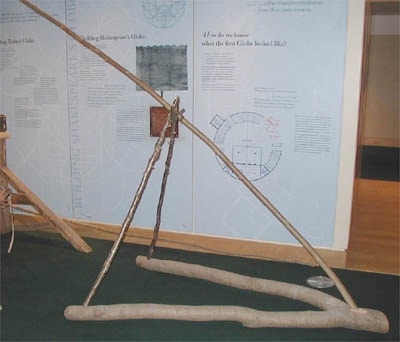

In my case, I needed a springpole that would be portable, would work both indoors (with low ceilings) and out, and didn't involve toting about a whole forest of poles. A common configuration uses a sturdy forked tree branch to serve as a base, such as this one on display at the Globe Theatre in London:

A very workable design, but not very compact.

Unfortunately, many period illustrations of springpole lathes neglect to show the springpole itself, or at least what it is attached to. One that does is from the Mendel Housebook, which shows a springpole mounted on an upright post:

For the springpole itself, I experimented with various woods and found that English Beech made a nice springy pole that didn't crack. Instead of a round pole, I used a long lath of beech about 1/3-inch thick and 2-inch wide, more like a leaf-spring than a pole. It gives a nice compromise, with enough stiffness for a crisp return, but not so stiff that it wears out my leg. It works nicely for spindle turning, though I suspect if I were bowl turning I would want something with a lot more strength.

Copyright 2009, Thomas Rettie.